Feathers for screw conveyors

We are a direct manufacturer of blades for screw conveyors, which are used to carry, mix, transport and dose elements such as cement, sand, gravel, dust, grain, fodder, sludge, granulates.

Our products meet high quality standards and ensure trouble-free operation of screw conveyors for a long time.

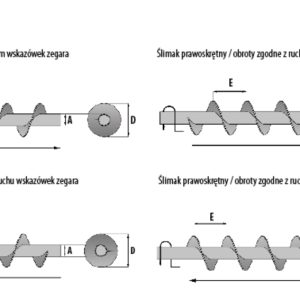

The specification of produced feathers and their coils depends, among others, on on the purpose of the screw feeder, the type of transported medium, the diameter of the screw feeder shaft, and the housing of the screw conveyor itself. We sell our worm blades: as single segments with a given stroke length, thanks to which the material thickness is the same along the entire height of the blade, or as ready-made elements welded onto the shaft. If you want to get a spiral or a shaftless screw, you just need to connect the individual coils and weld them together.

Additional information

Information leaflet

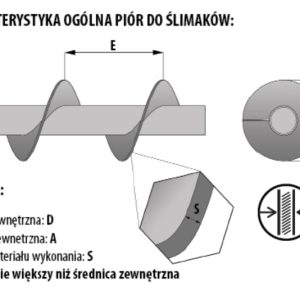

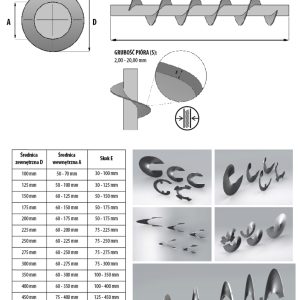

Our worm blades are single segments with a pitch length, thanks to which the material thickness is the same along the entire height of the blade. To obtain a spiral or a shaftless screw, it is enough to connect the individual coils together. Also, the replacement of worn coils is easier – just provide us with the necessary parameters, such as external diameter of the blade, pitch of the blade, internal diameter of the screw blade and we will efficiently produce for you the number of screw segments indicated for replacement.

Regardless of the place where they are to be used, our blades for screw conveyors and entire ribbons for screw conveyors are made of the highest quality steel, which is thoroughly checked before the manufacturing process in terms of the production process, strength and other factors affecting the life of the product .

We work only on sheets with a material certificate. Our blades for screw conveyors are manufactured, among others, made of structural, stainless, acid-resistant, abrasion-resistant, heat-resistant steel and welded with a wear-resistant weld. The type of material is adapted to the intended use and is selected so that the coils will last for a long time. Our products are manufactured with very high accuracy, care and repeatability. Our products are much easier to put on the conveyor shaft, their assembly takes less time and material waste is smaller. All this translates into saving work and money for our clients.

We carry out orders both on a mass scale and individual pieces. Our products meet stringent standards and ensure trouble-free operation for a long time. Thanks to over 10 years of experience and a high position on the market developed over the years, we are able to complete orders in the shortest possible time, while maintaining the highest production standards.

As one of the few in Poland, we have an innovative technology that allows for the formation of blades for screw conveyors only in the cold. Thanks to this method of production, the time for making the screw segments is shorter, and the repeatability and accuracy of production is at the highest level, which definitely affects the subsequent ease of applying the blades to the screw shaft. Thanks to the fact that we cut small wedges in the initial material, it is possible to extend the coil of the blade, which allows to reduce the target number of screw blades on the screw conveyor shaft and significantly reduces production costs.

Also, the replacement of worn coils is easier – just give us the necessary parameters, such as: external diameter of the blade, pitch, internal diameter of the blade and we will efficiently and quickly produce the number of screw segments indicated for replacement.

We can make segments for screw conveyors on special order, according to the customer’s wishes, using non-standard materials. Our customers can count on support and technical assistance. Feel free to contact us.